Nerve Repairs Using 3D Printing

Nerve Repairs Using 3D Printing

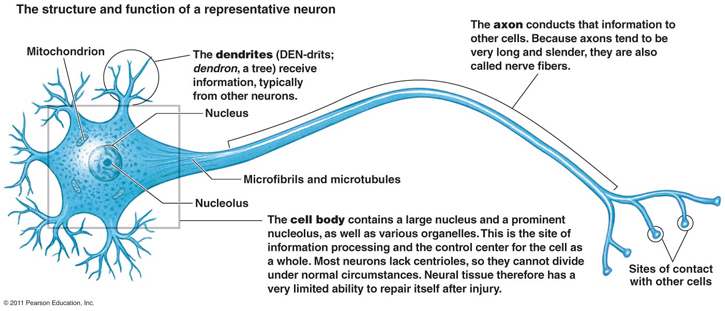

Nerves are how we feel pain. Nerve fibers also carry information to fire our muscles into action. These fibers are critical to say the least, and many of us have experienced some form of decreased or loss of nerve sensation in one part of our body or another. Disease, trauma and surgery can damage nerve tissues, sometimes quite severely, leaving patients with areas of major dysfunction. Nerve loss is a serious issue and thus I’m happy to report on a relevant bit of science seeing some solid advancement: the use of 3D printing to create plug-in connection points between severed nerve tissues.

3D Printing Guide for Nerve Regrowth

As there have been many successful uses of 3D printing in the building of custom, biomedical implants, a new 3D printed structure meant to “guide” the regrowth and reconnection of the loose, severed ends of a damaged nerve suggests that the technique could work well for neurosurgery.

The structure and function of a representative neuron. Image Courtesy: Pearson Education, Inc.

Nerve-related injuries are quite common, and doctors resultantly perform over 200,000 nerve repair procedures each year in the U.S. alone. The most common nerve repair surgeries entail using nerve tissue taken from another part of the body to fill a gap. However, this type of procedure requires an additional procedure to harvest the tissue, which can lead to chronic pain, sensory loss, or additional problems at the harvesting site. An alternative procedure involves using what can be considered an artificial scaffold, usually tube-shaped, which sits in-between the two ends of a broken nerve and acts as a conduit and guide for regeneration and re-connection. Coupled with biochemical cues built into the scaffold itself (via the 3-D printer), the nerves are prompted in which direction to grow.

Nerves and Nerve Injuries are Highly Complex

Nerve and nerve-related injuries are often highly complex and anything but straightforward. Many times it’s not just a single, point to point connection that is needed between severed nerves, but rather a web of disconnected fibers that must turn corners, go different directions. Here again, 3D printing allows for more complex designs to be printed into such guides or scaffolds…and once again, with biochemical cues. Indeed, according to Michael McAlpine, a professor of mechanical engineering at the University of Minnesota:

“But nerves and nerve injuries are often not so straightforward, and 3D printing technology makes it possible to design and make guides that are conducive to more complicated shapes.”

To show the new technique, McAlpine and his collaborators, including neurosurgeons and biomedical engineers, demonstrated in rats that they could regenerate an original Y-shaped structure modeled after a 10-millimeter piece of the rats sciatic nerve, including the point where it branches, had been cut out.

Here is a video showing this complex, Y-shaped nerve scaffolding being printed and then surgically implanted into the rat. It comes complete with the necessary biochemical cues that give the initial “spur to grow” instructions (you will see these chemical drops put in midway through the 3D printing process):

Video Courtesy: Rajamanickam Antonimuthu

Using a 3D scanner to record information about the missing pieces geometry, this data was fed into the researchers 3D printer. An intact, functioning sciatic nerve contains a mix of both motor and sensory nerve fibers at the base of the Y-shape. At the “Y,” it splits into branches that contain either primarily motor neurons, which send information to the muscles, or mostly sensory nerve fibers, which sends information to the brain. In the reproduction of the Y-shape with the 3-D printer, the same printer deposits the noted biochemical cues in the appropriate Y-branch. Red for motor neurons, green for sensory.

Likely Available For Humans in 5 to 10 Years

Michael McAlpine estimates the this new, nerve-connecting technology ala 3D printing could be ready for human testing in 5 to 10 years. However, there is still a good bit of work to be done. Here again, a quote from McAlpine talking about the road ahead:

“If the technology is to eventually advance to the clinic, it will not be essential that the missing piece of an injured nerve be available for 3D scanning, which is important because many injuries likely won’t afford that luxury. In that case, a corresponding nerve on the opposite side of the body may be able to stand in for scanning, or perhaps there could even be existing “libraries” of geometrical data based on nerves from cadaver models.”

Co-researcher and collaborator on the project, Xiaofeng Jia, a professor of neurosurgery at the University of Maryland School of Medicine adds:

“The new technique should be thought of as a starting point that “opens the door” for the development of new regeneration schemes that take advantage of 3D printing to make implants with complex shapes. It should be possible to use this approach to create more complicated branching designs suited for other nerves. And it’s also possible that alternative materials and biochemical schemes will be more effective at promoting the healing of injured nerves.”

Ideally, according to McAlpine, would be the use of a biodegradable material in the 3D printing process, which would dissolve in the body once it has served its guiding function. Let’s hope the future brings just that.

April 22

April 22